Researchers recently developed a new process to make the recycling of plastic more attractive. They presented a process that can turn the material into useful chemicals.

In recent decades, plastic has become increasingly suitable for everyday use. This is because the material is inexpensive to produce and at the same time lightweight. This has triggered a veritable packaging revolution. However, we are now seeing in many places that plastic could pose one of the biggest challenges alongside climate change.

One widely used combination is polyethylene (PE). This is the most commonly used plastic in the world and can be found in everyday products such as food packaging, shopping bags and reagent bottles. However, the majority of plastic is not recycled. The material therefore poses a major threat to the environment and ecology.

Photocatalyst: recycling plastic at room temperature

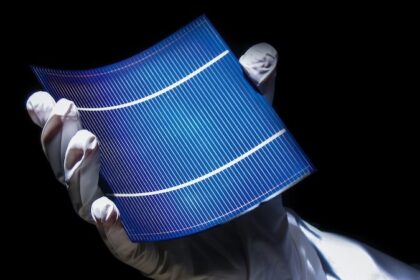

However, a new discovery could soon solve the problem. An international team of researchers has developed a new recycling method. They converted PE waste into useful chemicals using light-driven photocatalysis. The method only requires a combination of plastic waste, water, sunlight and a non-toxic photocatalyst.

In contrast to current chemical recycling methods, the process takes place at room temperature. By comparison, previous processes require a temperature of over 400 degrees Celsius. Almost 99 percent of the liquid end product of the new method is propionic acid. The chemical is in high demand due to its antiseptic and antibacterial properties.

Process is based entirely on the use of solar energy

An essential material for the chemical industry is created from plastic waste, some of which is toxic and hazardous. This also benefits the environment. This is because the plant uses renewable solar energy for the process instead of fossil fuels, which emit greenhouse gases.

The result is a green and sustainable solution that simultaneously reduces plastic pollution and produces valuable chemicals from waste for a circular economy. This should not only be good for the environment, but also save the industry millions in costs.