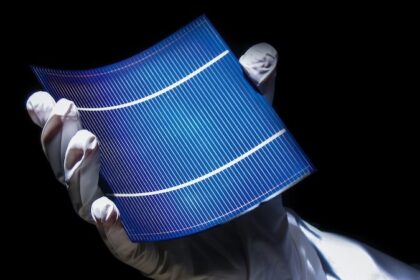

The South Korean company Qcells and US solar manufacturer Solarcycle want to increase the recycling of solar modules in future. The two companies want to prevent raw material problems and become more independent.

What actually happens to solar panels after their normal service life? More and more experts around the world are now asking themselves this question, as many systems will reach the end of their service life in the coming years. In the USA, the two solar companies Qcells and Solarcycle will therefore be working together in future.

While Qcells is the operator of the largest silicon-based solar panel factory in the United States, Solarcycle specializes in recycling methods for solar modules. The collaboration is the first of its kind in the industry and is intended to symbolize a significant step towards greater sustainability in the solar industry. This is because the Qcells panels are turned back into raw materials such as aluminum, silver, copper, silicon and low-iron glass.

The manufacturer then reuses these to produce the next generation of solar panels. Solarcycle claims that its patented solar panel recycling technology can extract more than 95 percent of a module’s materials.

Recycling solar panels creates 4,000 new jobs

This figure is at the upper end of the current industry standard for solar recycling. By comparison, First Solar, the largest solar company in the US, claims to be able to recover around 90 percent of materials. The Qcells plant in Dalton, Georgia, is the largest silicon-based solar panel factory in the USA. It has an expected production capacity of 8.4 gigawatts (GW) this year. In addition, around 4,000 jobs will be created in the region.

The Seoul-based company is thus pursuing a strategy announced a year ago. Quells intends to invest more than 2.5 billion US dollars in the development of the first complete solar supply chain in the USA. This is the largest investment in this sector in the United States to date. It includes the expansion of the Dalton solar factory and the construction of a fully integrated solar supply chain factory in Cartersville, Georgia.

Old solar systems become next-generation panels

The manufacturer plans to produce wafers, cells and complete panels there. Meanwhile, Solarcycle already operates recycling plants in Odessa, Texas, and Mesa, Arizona. The recycling company has also entered into long-term partnerships with more than 40 of the largest solar energy companies in the USA.

The initiative demonstrates the potential to make the solar industry more sustainable while reducing dependence on virgin raw materials. Against this backdrop, many new solar modules are likely to be made from old systems in future. This in turn will benefit the shortage of raw materials.