A Massachusetts Institute of Technology (MIT) researcher has developed a sustainable method for producing hydrogen. A solar reactor uses 40 percent solar energy for production.

In addition to the use of wind, hydropower and solar energy, one element could develop into an important pillar of the energy transition: Hydrogen. This is because, especially in energy-hungry sectors such as steel production, a switch to green electricity is rarely profitable.

At the same time, it needs an energy source for large vehicles. The use of battery technology for cars and hydrogen for trucks, trains and aircraft is becoming increasingly likely for the future. But how can hydrogen be produced as sustainably as possible and on a large scale?

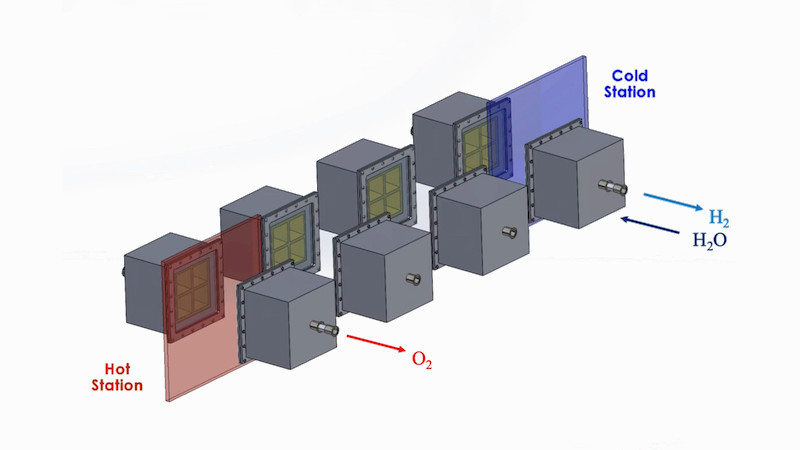

A team from the Massachusetts Institute of Technology (MIT) has now developed a solution. Their new solar reactor system can produce hydrogen directly from water and solar heat.

Hydrogen from solar reactor based on heat from the sun

Until now, the use of so-called solar-thermochemical hydrogen has been rare. This is because the conversion of sunlight to produce the element was just seven percent. With their solution, the MIT team wants to use up to 40 percent of the incident heat to produce green hydrogen.

The researchers even go so far as to say that a kilo of hydrogen should cost just one U.S. dollar by 2030. Currently, the price is around four to six euros per kilogram, provided solar or wind energy is used. A solar heat source provides the necessary energy, and the reactor then splits the water into hydrogen and oxygen.

Approach still poses some challenges

The water evaporates and comes into contact with a metal. The metal absorbs the oxygen from the steam and oxidizes (“rusts”). What remains is pure hydrogen, which can then be transferred to tanks. After cooling, the metal is then available for another cycle.

But there are some challenges. For example, the metal needs a vacuum to efficiently de-rust again after the process. Storing the heat is also still a problem. This is because temperatures of over 1,000 degrees Celsius sometimes prevail in the reactor. In the next step, the team wants to build a prototype to test the system in practice.